What Are The Benefits Of Plastic Injection Molding?

Plastic injection molding is a versatile method of producing products and parts. Since this method promises a number of advantages over other plastic molding methods, it’s one of the preferred methods for manufacturing parts. Plastic injection molding isn’t just reliable and simpler, it’s also very efficient. You should have no doubts about using this method to manufacture parts.

Here, our plastic injection molding company expands on the benefits of injection molding:

What is plastic injection molding?

Injection molding is a manufacturing process that allows parts to be produced in huge volumes. It works by injecting molten materials into a mold. Normally, it’s used as a mass production process to manufacture tons of identical items. Injection molding materials comprise all kinds of plastic resin, although it’s most commonly used with thermoplastic and thermosetting polymers.

Benefits of plastic injection molding

Wide acceptance

Plastic injection molding is one of the most popular manufacturing processes. Almost every industry in the world is transforming its manufacturing processes and is looking to replace metal parts with plastics. This is due to similar strength levels with more precise designs and higher durability.

Cost efficiency

The process of plastic injection molding is computerized and doesn’t include a lot of human intervention. Thanks to the introduction of robotics and advanced machinery, the plastic injection molding process has truly evolved. Due to the reduced labor costs, the process has become more cost-efficient. There’s no doubt that reduced labor costs have significantly cut the costs of manufacturing the products.

The process of plastic injection molding is computerized and doesn’t include a lot of human intervention. Thanks to the introduction of robotics and advanced machinery, the plastic injection molding process has truly evolved. Due to the reduced labor costs, the process has become more cost-efficient. There’s no doubt that reduced labor costs have significantly cut the costs of manufacturing the products.

However, it isn’t the only factor. Other crucial reasons comprise the ability to create accurate, precise parts in one go. CAM (Computer-Aided Manufacturing) along with CAD (Computer-Aided Designs)help in producing parts without the need to recreate. This doesn’t just reduce the overall manufacturing time but the associated costs as well. This cost-efficiency is also due to the high mass production output.

While creating molds can be costly upfront, the costs go down significantly in the long term. This is because multiple volumes of plastic parts can be produced within the same cost (a single mold).

Compared to injection machines, traditional plastic machines can cost around 25 times more in the long run.

Waste reduction

Environment considerations should go hand in hand with industrial manufacturing processes. This holds especially true for the plastic industry, which generates the greatest amount of non-biodegradable solid waste. Plastic pollution or plastic waste accumulation around the world has risen of late, reaching undesirable levels. This is destroying the natural habitats and ecology.

Compared to traditional machines that cut pieces of plastic from bigger blocks and produce a lot of waste, plastic injection molding uses just the required amounts. Hence, plastic injection molding isn’t just more efficient (especially when producing lighter, smaller parts), but also produces far less waste compared to conventional techniques.

Many leading plastic injection molding manufacturers are dedicated to green, sustainable initiatives. The excess plastic produced during the molding process is recycled through state-of-the-art machinery, thus mitigating the waste generated.

Low labor cost

The ability to manufacture plastic parts in bulk with high output ratio and minimal time makes the process of plastic injection molding extremely efficient with respect to cost. This is one of the reasons why this process doesn’t involve a lot of labor costs.

In addition, the molding equipment doesn’t require much supervision. The self-gating tool streamlines both the production and the operations with minimal human intervention.

Computerized injection machines, automated fabrication, and 3D computerized design units work to manufacture high-quality parts without much labor. Plus, the inclusion of automation reduces the probability of human error, thus adding to the long list of benefits.

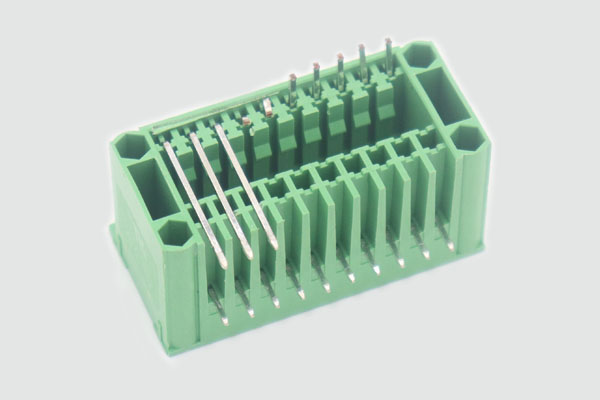

Simultaneous use of several plastics

This is a major advantage of plastic injection molding. Different plastics have different properties suitable for various industrial processes. The ability to use different types of plastics at the same time is an attractive practice that’s only possible with plastic injection molding.

Different plastics are needed in situations where it’s required to change basic plastic properties such as texture, color, elasticity, density, and other mechanical properties of the material.

With co-injection molding, molding companies can use different resins to create a material of choice. In addition, the use of different polymers together helps in reducing the total cost of the material.

Flexibility

The need to have the right finish, material and colors are the most essential factors in the plastic industry. And to be fair, the choices are endless. With the advancement in the world of polymers and modern technology, an array of plastic resigns have been identified. Thus, there’s an enormous selection to choose from

The need to have the right finish, material and colors are the most essential factors in the plastic industry. And to be fair, the choices are endless. With the advancement in the world of polymers and modern technology, an array of plastic resigns have been identified. Thus, there’s an enormous selection to choose from

The finest plastic injection molding companies are experienced and working with a huge number of resins as well as with complete knowledge of resin selection for a specific project. The selection of resins for a project depends on the following factors:

- Flexural modulus of elasticity

- Water absorption

- Heat deflection

- Impact strength

- Tensile strength

Numerous coloring techniques are available for adding shades. In addition, multiple finish appearances such as unique textures, matte, or smooth surface finish are possible with plastic injection molding processes.

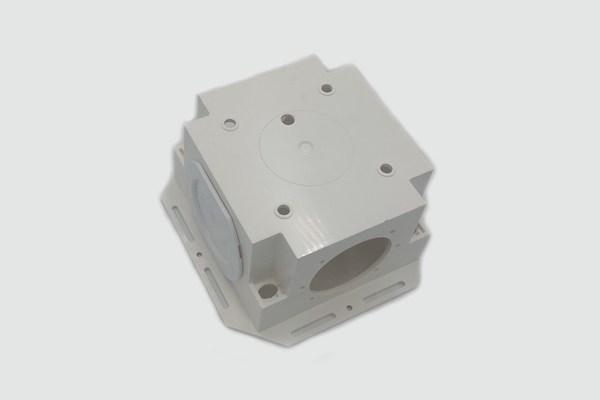

Great strength

Plastics have changed over the years. Today, increased precision, durability, and strength is an integral requirement of every industry. Sturdy, lightweight plastic parts are now being used even in the most rugged environments.

In contrast to traditional machines, plastic injection molding makes it possible to add fillers within the injection molds.The fillers comprise materials like clay, glass, alumina trihydrate, mica, calcium carbonate, silica, etc.

The fillers are specially chosen to add stiffness/strength to the material. These fillers work by reducing the overall density of the plastic during the process of molding. This results in better strength of parts that are being molded. In addition, certain fillers also add to the heat resistance properties of the plastics.

Numerous industries such as the auto industry entail small plastic parts that should be very durable and strong. Conventional molding machines had their limitations in this aspect. However, plastic injection molding makes it possible to mass-produce a ton of high-strength plastic parts.

Efficiency

CAM and CAD processes are used to design injection molds. The designs are created as per the specifications of the customer.

Once the molds are ready, the actual production process is very fast. Compared to traditional methods of molding, injection molding is very quick even when mass production levels are needed.

The plastic injection molding process isn’t time-consuming. Since the process is very swift, parts can be produced in bulk from a single mold, thus creating a high production output rate.

The precision with intricate designs

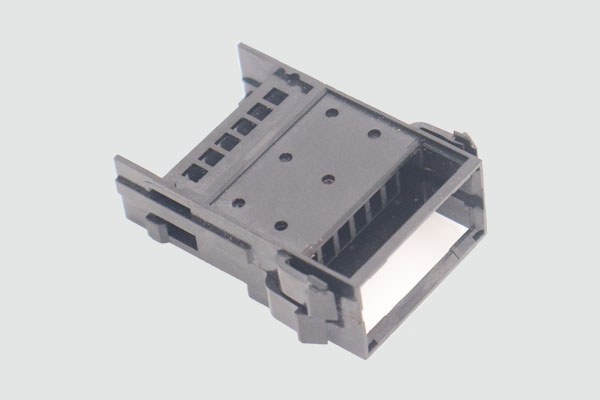

The techniques that plastic injection molding uses allow for the creation of complex designs and add a huge number of details to the parts. Since the injection molds are exposed to high pressure, the plastics are pressed harder, making it possible to manufacture complex designs.

Of course, all of this isn’t possible with a traditional molding machine. With plastic injection molding, fabrication of plastic parts can be created to a precision level within 0.001 inches. In addition, since the process is entirely automated, even the most complicated designs are comparatively cheaper to manufacture.

Design flexibility

The ability to be flexible in designs is one of the main reasons why plastic injection molding has been so successful. Due to the flexibility associated with this technique, the clients like to work with plastic parts. Whether it’s about being flexible in terms of color choices, creating accurate designs, or choosing multiple plastics, the process of plastic injection molding can help. This enables the users to manufacture designs of their choice, which is a huge change when compared to conventional molding processes.

The ability to be flexible in designs is one of the main reasons why plastic injection molding has been so successful. Due to the flexibility associated with this technique, the clients like to work with plastic parts. Whether it’s about being flexible in terms of color choices, creating accurate designs, or choosing multiple plastics, the process of plastic injection molding can help. This enables the users to manufacture designs of their choice, which is a huge change when compared to conventional molding processes.

Drawbacks of plastic injection molding

Small runs of parts can be expensive

Since tooling is complex, and it’s important to remove all previous material from the machine before the next product can be manufactured, the setup may take some time. Therefore, small runs of parts have always been thought of as too costly to injection mold.

Part design restrictions

Plastic parts must follow the basic rules of injection molding and be designed with injection molding consideration. For instance:

- Draft angles are encouraged for better de-molding

- Use uniform wall thicknesses to prevent inconsistencies in the cooling process leading to defects such as sink marks

- Avoid sharp edges and undercuts as much as possible

Since tools are normally made from aluminum or steel, making design changes can be difficult. If you’re looking to add plastic to the part, you can make the tool cavity bigger by cutting away aluminum or steel. However, to take away plastic, you should add metal or aluminum to the tool cavity to decrease its size. This is very challenging and, in most cases, may mean scrapping the tool (or part of it) and starting right from the beginning.

In addition, the size and weight of the part will determine the tool size. The bigger the part, the more expensive and difficult it will be.

High tooling costs

Since tooling, testing, and design are required, upfront costs are high. There’s the initial design and prototyping (probably via 3D printing or CNC), then the design of a prototype mold tool to produce replicas of the volume part. Lastly, once extensive testing during both stages comes to an end, injection molding a part becomes possible.

Verdict

OEMs (original equipment manufacturers) across a variety of industries can attest to the advantages of plastic injection molding. It’s perfect for affordable, consistent production of an array of high-quality complex plastic parts that can withstand about any environment. That’s reason enough to rank plastic injection molding high on the list of the best solutions.

Despite some of the disadvantages mentioned above, injection molding is still an incredible process. The range of colors and materials is enormous. Parts are repeatable and the tolerance is tight. The only main downside is the tooling, but PTMS has got that covered.

Why should you work with an experienced plastic injection molding manufacturer?

If you want to truly leverage the benefits of plastic injection molding, manufacturers must seek out knowledgeable custom injection molders that know how to maximize efficiency and overcome any process or design issues that may surface.

Having the best materials, technology, and equipment will only get you so far — it’s having the most experienced, the best tooling partners and injection molding engineers that will really make a difference in your final quality, costs, and lead times.

Before agreeing on an injection molding company for your project, ask these critical questions:

- Do they understand the nature of your products and the intricacies of your industry?

- Do they have robust testing procedures and QA/QC?

- Do they have in-house maintenance capabilities and tooling design?

- Do they have over-molding and scientific molding capabilities?

- Does the molder have in-house engineering expertise?

If you can answer ‘yes’ to all these questions, you know you’ll be selecting an experienced partner you can trust to deliver the expertise, value, and quality needed to affordably produce intricate injection-molded parts.

Get top-quality custom plastic injection molding through PTMS — the finest plastic injection molding company in China!

As one of the leading plastic injection molding companies, PTMS has been offering top-quality custom plastic injection molding mass production to its customers since 2002. With experienced employees and advanced injection machines, PTMS knows how to control the cost in a reasonable range.

As an ISO9001-2008 certified injection molding company operating for more than two decades, PTMS has injection molders who provide one-stop service from mold design, mold making, injection molding mass production and products assembly for a holistic custom manufacturing experience.

Give them a call for more information about their plastic injection molding company!