Top Tooling Tips to Ensure Perfect Plastic Parts

Did you know the global market size of the plastic industry is at 593 billion dollars and is expected to increase in the future? It’s no secret that plastic is an integral part of the manufacturing industry. However, amidst the global supply chain crisis, many companies find it difficult to acquire top-quality plastic parts at the right time. In such circumstances, businesses are looking for innovative solutions to get their hands on top-class plastic parts.

Looking to dive deep into the plastic manufacturing world? With the right tooling tips, you can ensure that your parts are precise and accurate, with a smooth finish. Check out these top tooling tips to help you achieve perfect plastic parts every time! From choosing the accurate material to proper design and assembly, these tips will help you streamline your process and avoid common mistakes.

Focus On Mold Design

Designing a mold is one of the most crucial steps in the plastic parts manufacturing process. With the right design, you can ensure that your parts are precise and accurate, with a smooth finish. Here are some tips to help you design the perfect mold:

- Select the right material: The type of material you use will impact your product’s properties. You must select a material that’s compatible with your manufacturing process and meets your requirements.

- Pay attention to detail: Focusing on intricate details can make a massive difference in your product’s quality. Consider designing your mold precisely and pay close attention to surface finishes.

- Streamline your design process: A well-designed mold can help you streamline your manufacturing process, saving time and money. Make sure to consider all aspects like injection molding and packaging when designing your mold.

Always Conduct Tool Testing

Consider conducting tool testing before you begin manufacturing plastic parts. It’ll help you ensure that your tools are in good condition and that you can produce high-quality products.

Testing also allows you to catch potential problems early. When testing your tools, focus on factors like cutting pace, surface finish, and dimensional precision. By conducting regular tool testing, you can avoid potential issues down the line and ensure that your plastic parts are perfect every time.

Avoid Undercuts

One of the most common mistakes in plastic manufacturing is creating an undercut. An undercut is when a portion of the tooling prevents the part from being ejected from the mold. Fortunately, there are a few ways to prevent undercuts:

- Use proper mold design: You must design the plastic injection mold with adequate draft angles to prevent undercuts.

- Avoid complex geometries: Undercuts are more likely to appear with complex shapes. Simplify your design to minimize the risk of an undercut.

- Use proper assembly: Ensure that you collect all mold elements accurately before starting production. It’ll help avoid any misalignment that could lead to an undercut.

By following these tips, you can avoid the costly and time-consuming mistakes that can occur with undercuts. With proper planning and execution, you can manufacture perfect plastic parts every time!

Select Proper Resin

When selecting a resin for your project, evaluate what type of product you want to make. For example, if you require a clear plastic part, you’ll want to choose a resin with transparent characteristics.

Alternatively, if you need a strong plastic product, select a resin with high strength and stability. By researching thoroughly beforehand, you can avoid costly mistakes and ensure that your products meet all requirements.

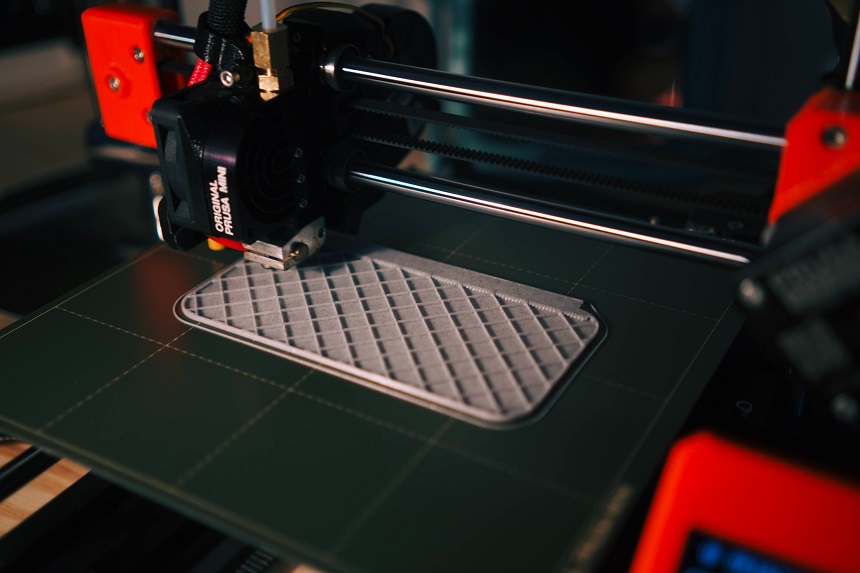

Use Rapid Prototyping

Want to manufacture perfect plastic parts? Start rapid prototyping as soon as possible. With rapid prototyping, you can create a prototype in no time without worrying about precision and accuracy.

You can test your design and ensure that it works before you kickstart the manufacturing processes. Additionally, rapid prototyping can help you identify any potential problems before you start manufacturing. You can use a prototyping strategy to save time and money in the long run. Here are some rapid prototyping options that can be helpful for your company:

Metal 3D Printing

When it comes to manufacturing plastic parts, metal 3D printing is a great option. With metal 3D printing, you can create strong and precise plastic parts. You can also use it to make plastic parts with complex shapes.

CNC Machining

CNC machining is a popular manufacturing process for plastic parts. With CNC machining, a computer controls the movement of the cutting tool and amplifies product precision. You can use this process to create intricate shapes with complex characteristics.

When machining plastic parts, you must select the correct material. Some plastics are more difficult to manufacture than others, so you must consult with a reputable manufacturer like PTMS. Proper design and assembly are also critical for successful CNC machining. If you don’t design the parts correctly, they may not fit together properly.

Rapid Injection Molding

Rapid injection molding is a versatile and efficient manufacturing process for producing high-quality plastic parts. You can use plastic injection molding for mass part production, but with advances in technology, it’s now possible to create small batches of plastic parts quickly. Rapid injection molding is ideal for producing parts with stiff tolerance levels and complicated designs.

The process begins with a Computer-Aided Design (CAD) file or 3D model. You’ll have to transfer the design to a tooling company to create the mold for the part. Once the mold is created, the manufacturing process can begin. Rapid injection machines can rapidly inject molten plastic into the mold. The high speed and accuracy make injection molding an ideal solution for low and high-volume production companies.

Experienced Injection Molding Company Can Help You Get the Plastic Products You Need

Looking for a reliable plastic injection molding company? You’ve come to the right place! At PTMS, we’ve been working as a licensed injection molder since 2002. We assist clients in various industries, including medical, printing, automotive, and electronics.

Our team offers multiple services like mold design, mold making and injection molding mass production. We’ve got an exceptional research team that works round the clock to manufacture new products.

So, what are you waiting for? Contact the representatives at PTMS for more details about their injection molding manufacturing services.