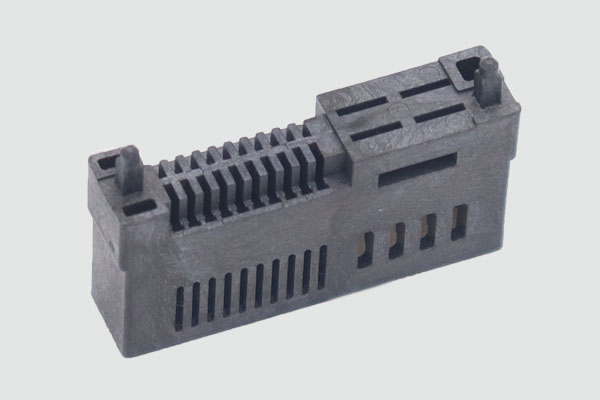

Tooling Tips for Creating the Perfect Part Mold

A top-notch injection molding tool is arguably the most important factor to produce a high-quality plastic product.

Here, we discuss some tooling tips to create the perfect part mold.

Strong mold design

To get precision parts, exacting standards must be met, in both the design of mold components and in the cavities. It’s important to place gates correctly, as they allow for proper pressure and melt flow. Another important consideration is the gate’s size. The gate shouldn’t extend the cycle time, while it should be large enough to offer appropriate packing of the material. If the gate is very small, the part may either display other defects or the packing may not be sufficient to fill the cavity.

The mold’s design should also come with vents because they allow the air to escape the tool. Like gating, the position and size of the vents are important factors in manufacturing a high-quality part. If the vents are too large, they enable the plastic material to escape, which may cause flashing.

However, vents shouldn’t be too small either as they may fail to release enough trapped gas and air. The gas may combust, causing burn marks on the part.

Machining to exact standards

A shrinking resin may impact the machining and design of the tool cavities. The cavities should accommodate for the degree of shrinkage that may occur.

A shrinking resin may impact the machining and design of the tool cavities. The cavities should accommodate for the degree of shrinkage that may occur.

The design engineer will use modern CAD software to create cavities that are bigger than the actual finished part. The size of the allowance depends on the resin’s specific properties. While some of this shrinkage could be dealt with by regulating the holding and packing rate in the mold, every plastic shrinks when it cools, even after the part is no longer in the mold.

In the worst-case scenario, you’ll witness warpage when a part has molded-in stress, which is mainly due to issues with venting, gate location, flow rate, temperature, or pressure.

Get top-quality custom plastic injection molding at PTMS

PTMS is the best plastic injection mold maker in China and has been providing top-quality custom plastic injection molding to its customers for a decade. Thanks to its skillful employees and top-of-the-line injection machines, PTMS knows how to control the cost in an appropriate range.

Give them a call for more information on their plastic injection parts!