The Disadvantages of Cheap Plastic Injection Molding

Do you know the disadvantages of cheap plastic injection molding? Today we will discuss the disadvantages for the related industries. Being a professional injection molding factory, we knew some importers would like cheap injection molding because of the low price, they want to make big profits, so the business will be better? In my opinion, it’s a very bad idea, the quality will be very bad if cheap ones. From our side, some comments will be shown as below.

1. The mold quality will be poor. If people like cheap injection, that means the cost of injection mold is low, bad design, bad making, the factory will save much money from the mold, short mold life, bad mold components, bad simple mold design, this mold will be broken sometimes, it takes many funds to modify them.

2. The plastic resin will be bad quality for mass production. If you want the parts made by cheap injection molding, the factory will order the bad original plastic resin for your parts, this will save a lot of money. We can’t know how about the parts quality from the outside, all parts look very good at the first time, but we have to tell you the truth, the cheap parts will be broken after 6 months or 1 years later.

3. External parts mean plastic cover, plastic case, normally the plastic resin includes ABS, ABS+PC, PC and etc. the characteristic include good hardness, fuel injection, impact resistance, durability, crack prevention and collision avoidance. So many the original materials of external parts will be used by such resin. As we know, outside parts is very important, the quality will be bad if you need cheap ones, the shop will use the cheap plastic resin for custom plastic injection molding mass production, the shop want profits, but you can’t give them good price and like cheap ones, so the shop will order bad resin with low price. Finally, your customers are not happy with the quality, because you provide cheap plastic injection molding to them.

4. Internal parts mean the parts used inside, also called functional parts. these parts are focus on functional not the surface, some flash or other point are not a big problem. Normally, plastic resin includes PA6+30%GF, PBT+30%GF, PP+TPU, POM and etc. they have good durability and strength. If you want cheap ones, the factory will order bad resin with low cost, the parts will be broken easily, 3 months or 6 months. Others bad things, we can’t list all one by one, you can check some if interesting from internet or books.

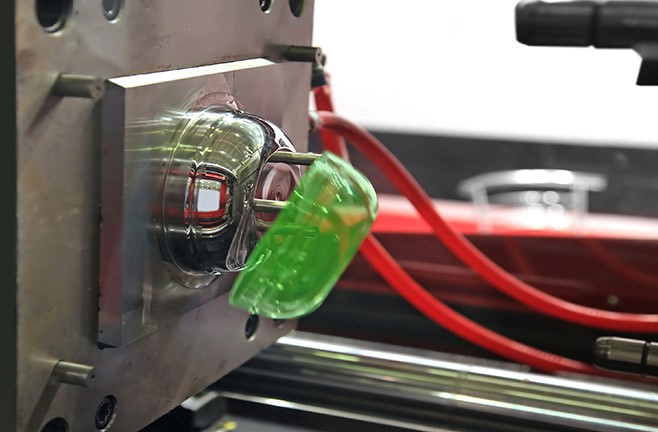

In summary, we can know the bad influence from above points, as a credible plastic injection manufacturer, PTMS don’t provide cheap injection molding for our clients, because quality is our life, our shop always makes quality molding since 2002. Here is one precision connector made by our shop, you can see the quality, it is used in electronic products, internal parts, just connector, quality plastic resin for mass production. If you need such service, just contact us, PTMS will be happy to work with you.