The Benefits of Plastic Injection Molding

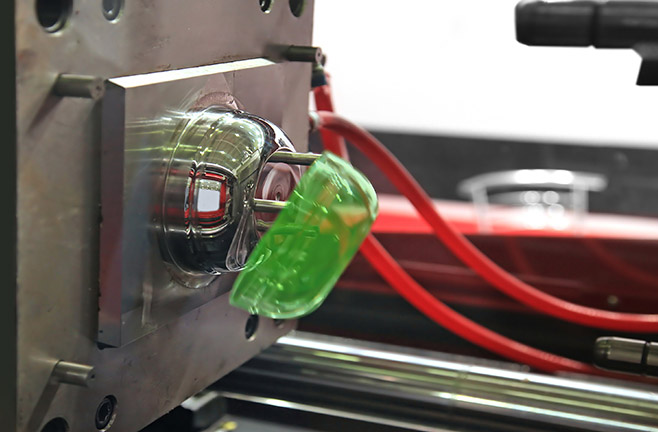

Thanks to plastic injection molding, manufacturers can produce plastic parts in bulk—and in a cost-effective, efficient, and fast manner. During this process, molten plastic is injected into stiff frames or molds, and then pressure is applied as the plastic cools and solidifies.

Here are some benefits of this process:

1. Material and color flexibility

When designing original parts, manufacturers can opt for commercial materials and colors. But before choosing the material and color, manufacturers should consider the factors of water absorption, heat resistance, lightness, attractiveness, durability, strength, and reliability. With improved developments, colors can be chosen. Plus, the over-molding technique can also be used if a manufacturer wants a multi-colored product.

2. Ease of using multiple plastics

Injection molding can use a range of plastics simultaneously. Using the co-injecting molding technique, the manufacturing parts can easily build the final products. The system is quite smart as it doesn’t care about the type of material being used.

3. Cost-effective

Plastic injection molding is a very cost-effective and efficient process. Because there are a ton of moldability options and the probability of problems remains low, this process is widely regarded as an acceptable and operational technique. The complex parts are produced at optimum capacity when the production is open round the clock.

Yes, injection molding is a cost-effective process, but there’s another advantage that industrialists love: lower labor costs. Because the manufacturing equipment is automated, robots or machines perform the processing. The entire process is managed by a single human operator, which brings down the labor cost by a country mile. With lower manufacturing costs and headcounts, customers are also able to save a lot more. Injection molding allows people to buy high-quality products without burning a hole in their pocket.

4. Design detail and development of complex parts

With this method, complex parts can be easily built. In fact, manufacturers can make an array of complicated shapes through excessive high-pressure inserts during the molding process. If there’s no high pressure, it would be impossible to make complex, detailed parts. However, injection molding can make high-quality, identical products in bulk.

5. Fast, highly efficient production

Compared to other production methods, injection molding offers super-fast speed and efficiency. Due to this, the process can manufacture products in bulk within a small timeframe. It doesn’t take long to produce complex plastic products, and that’s why products are manufactured in large quantities, cost less, and increase profit margins.

Get top-quality custom injection molding parts with PTMS!

PTMS is one of the leading plastic injection molding companies in the world and produces top-quality custom injection molding parts for its clients. Our products are widely used in different industries.

We’re an ISO 9001-2008 certified company with worldwide customers from a range of different industries.

Contact us now for an instant injection molding quote!