Somethings about Plastic Injection Mold Making Company

The purpose of plastic injection mold making company is to make all kinds of quality injection molds, but do you know the feature of the molds? Today we will share some feature of quality tooling with you.

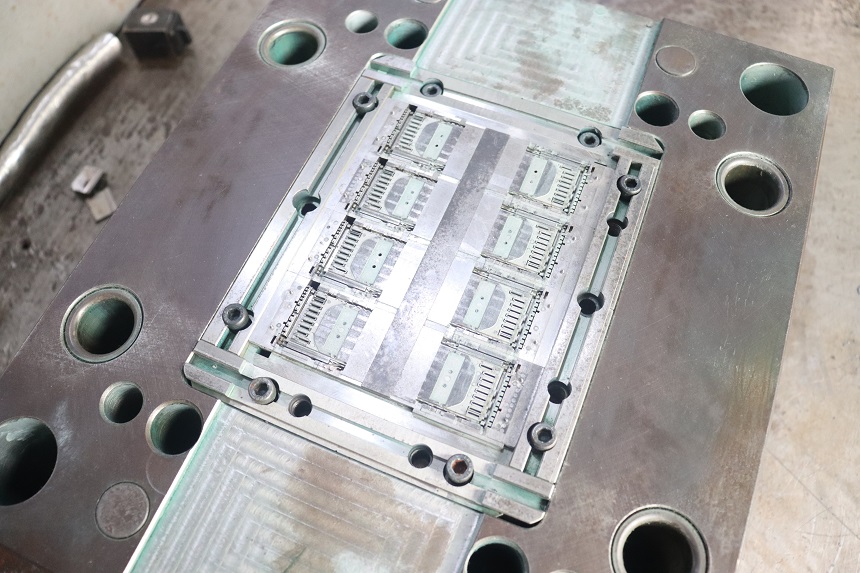

Reasonable structure design. The mold design is based on the 3D drawings of plastic parts or the samples, it should be easy for demoulding, easy for mold making and tooling. The simple design is the best, not too complex, but the simple design is difficult to be done and the professional engineers can design it, they should consider the core and cavity numbers, how to compose the parts to one mold, sometimes family mold design is very good, because the interchange core/cavity can cut down the cost. Sometimes it needs some sliders if difficult to demoulding.

The high-quality materials. All the components of the mold are very important, so the materials should be high quality for quality molds. The different parts should be used for the different mold core/cavity, the common materials include P20, NAK80, 718, etc. Meanwhile, the standard of the mold base is also high quality, which are HASCO, DME, RABOURDIN, JIS and LKM or other standard the customer request. The professional injection mold making company will pay more attention to the mold materials, because this can make sure high-quality molds.

Good surface treatment. The common treatment includes texture Hatching, EDM Hatching, Polishing, Diamond Polishing, etc. this is also very important, because good treatment will make perfect injection parts when plastic injection molding mass production.

Long mold life. It depends on the steel hardness, the plastic material and mold materials. Usually, the heat treatment steel is HRC 48~50°, the short common mold life should be 300 000 shots at least. The long life can save a lot of money for the suppliers and cut down the price of products.

The reasonable price. High quality plastic injection mold tooling should be reasonable price, low price is not good for mold, because too low cost can’t make good molds, besides, expensive mold can’t be accepted. So, the reasonable price is good for molds. There are many plastic injection mold making companies in the world, but not everyone can provide such price.

Shorter deliver time. Normally the lead time will be 35-45 days for mold making and the molds will be shipped to the customers. If you need to find a professional shop to make molds, high quality mold should have the above features, but there will be some other different features, we need to study and share in the future.

PTMS is a leading injection mold making company in China, we started to make injection molds since 2002, much experience in mold making, enough tooling machines, such as CNC, Wire Cutting, EDM, Grinder machines and others. We would like to make quality injection molds to the worldwide people as soon as you choose us.