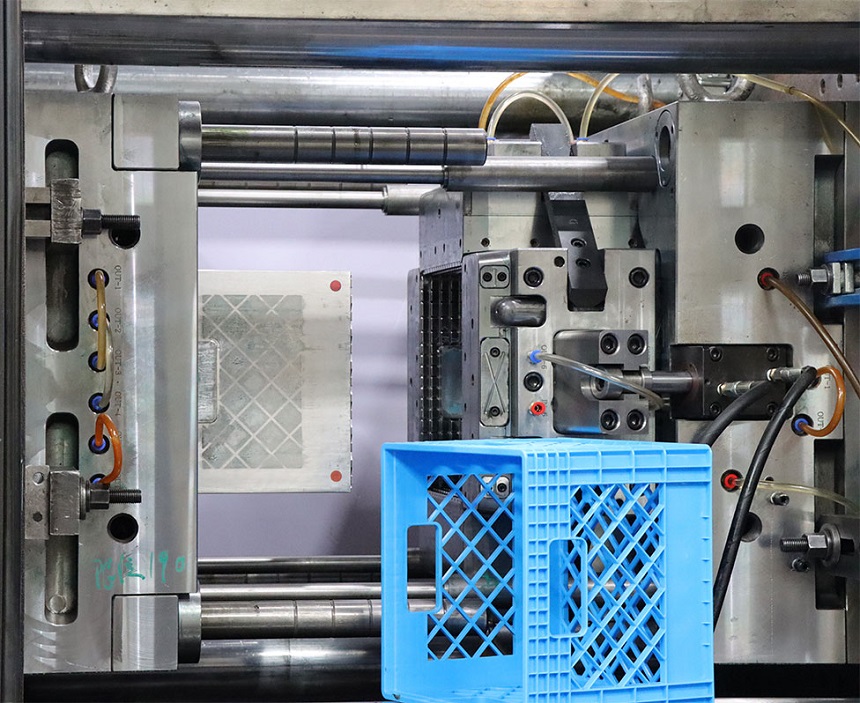

Plastic Injection Mold Maintenance & Care

The process of using high pressure to inject molten material into metal molds is known as plastic injection molding. Once the finished part is sufficiently cooled, it’s automatically ejected. The process is automated and can create large product volumes, especially plastic parts. To achieve these large volumes, preventative maintenance is important. Mold maintenance is important if you want to keep tools ready for production.

If mold isn’t maintained well, they made produce parts that fail to meet specifications, thereby affecting the bottom line, wasting raw materials, and causing extra downtime.

Here, we discuss how you should care for your plastic injection mold:

Major maintenance

Each mold must undergo major preventative maintenance between 500,000 and 1 million cycles. You should measure the alignment features of the mold, compare them to their ‘new’ baseline condition, and replace them if needed. You should then measure every other component to the original print dimensions and put it back in new condition. You must clean all water passages in the mold by removing every water fitting, baffle, and pipe plug.

If the mold cavity is degraded, you must refurbish it. When everything is done, you should rebuild the mold in better conditions and put it back to work.

General maintenance

Depending on the mold’s complexity, you should perform larger-scale general maintenance according to the number of times the mold has been run or cycle count. Basic open-and-shut molds without intricate action should get general maintenance between 250,000 and 500,000 cycles. However, a mold with a variety of moving parts needs an in-depth look, so perform their general maintenance every 100,000 cycles.

You should inspect the last shot of parts from the mold for defects or damage. If everything is good to go, you should start disassembling the mold completely. You should replace O-rings, check vent depths, and clean and inspect mold plates for signs of wear. If you come across any part of the damaged or defective mold, repair it. If the mold is equipped with a hot runner, inspect the conditions of the components and check it for signs of leakage. Then, prepare the mold for storage or production after reassembling it and running it through a systems check.

Clean and grease

This is probably the lowest form of preventative maintenance. This isn’t done on each mold but is completed on molds that need more regular attention due to the intricacy of the material used to create a part. Some resins produce more build-up and gases, requiring the mold to be cleaned frequently. You should clean the mold parting line and apply appropriate lubrication to moving components. You must also check for wear and damage as it may affect the part’s integrity and the mold’s operation. This maintenance is quite simple and can be performed while the mold is in the press. Generally, the frequency is anywhere from 5,000 to 50,000 cycles.

Get incredible mold project solutions with PTMS— the leading injection mold maker in China

PTMS has been a professional injection mold maker since 2002, offering customers of every size injection tooling for both low and high-volume plastic molded parts.

Give us a call now for more information!