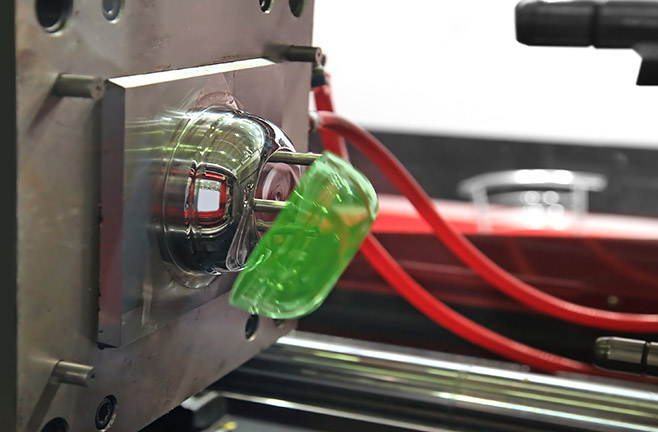

Injection Molding Tolerances: Best Practices

Compared to parts with tight tolerances, normal injection molding tolerances are typically less costly to manufacture. This is why coming up with a specific part or the optimal tolerance is important to produce top-notch parts at affordable rates.

Here, we discuss some best practices for improving injection-molding tolerances.

Choose the ideal material for the application

A material may considerably impact the tolerance of injection-molded parts, which is why material selection and part design are equally important. Injection molding is compatible with an array of plastic resins, the mechanical characteristics of which can be modified or strengthened with stabilizers, fillers, and additives.

Thanks to injection molding, it offers enough flexibility in material choice to benefit product teams. This allows these teams to improve and refine the material and performance qualities they’re looking for in a particular application.

The shrinkage rates of different resins are different, which must be factored into both the design of molding tools and the material selection. If part assembles include components from more than a single material, don’t forget to consider different shrink rates to guarantee that the individual pieces fit together. To ensure consistency in plastic injection molding tolerances, understanding the properties of particular resins is crucial.

Design parts for manufacturability

To prevent time-consuming, costly redesigns during later phases of production, it’s important to anticipate tolerance concerns early in the design stage.

To minimize the potential for part misalignments and warping, designers must ensure that they’re complying with DFM (design for manufacturability) best practices. DFM principles require designing parts with a specific method of manufacturing in mind. Both the manufacturing method as well as its unique restrictions must inform factors like design features, draft angles, and wall thickness.

To prevent uneven shrink rates, maintaining uniform wall thickness is important. Otherwise, deformities may emerge, which can inhibit the part’s ability to hold tight tolerances. In most cases, design features such as support ribs are more effective and efficient in offering strength than increasing wall thickness.

Draft angles are important to ensure the components eject easily from the mold without suffering scrapes or warping. Based on the desired surface finish and part design, appropriate angles naturally vary. However, a couple of degrees of the draft is generally a safe minimum for the majority of injection molded parts.

Bosses are raised part features typically used for fastening multiple plastic components together during assembly. If bosses are made very thick, they can lead to sink marks. Moreover, if bosses aren’t attached to a part’s sidewalls (mostly done via support ribs), they become prone to warping or distortion, which may considerably affect the ability of components to fasten together.

Get custom plastic injection molding services from PTMS

As an ISO 9001-2008 certified plastic injection molding company, we’re quite strict with the product quality. We have 8 QC technicians for every shift in the shop who inspect the samples via inspection equipment.

Contact us now for more information about our plastic injection molding service!