Injection Molding: The 3 Essential Components

Plastic injection molding is one of the best methods for producing plastic parts. Thus, it doesn’t come as a surprise that the global market for the process was valued at around USD 260 million, with forecasts for continued growth in the foreseeable future.

The technology is used in a range of industries, including automotive, medical equipment, and aerospace, where advanced techniques like insert molding are used to produce even the most complex parts with flawless precision.

Plus, injection molding offers a plethora of benefits, allowing millions of companies around the world to bring their part designs to life.

Here, we discuss the 3 essential components of injection molding:

The molding

Molding comprises the following components:

- Gate: It’s the opening through which the compound is injected into the mold.

- Runner: It’s used for allowing the compound into the mold’s cavities.

- Sprue: It’s part of the molding used for introducing the right compound into the molding process.

Molds must have multiple cavities leading into the mold to enable the easier, faster, and more efficient process of filling the mold with the compound. In addition, this allows for more products to be manufactured with a single filling.

Lastly, molding is often designed in a way that it has the same runner length as each of the sprues. This may ensure simultaneous filling of the mold in the same amount of time. This further speed up the injection molding process.

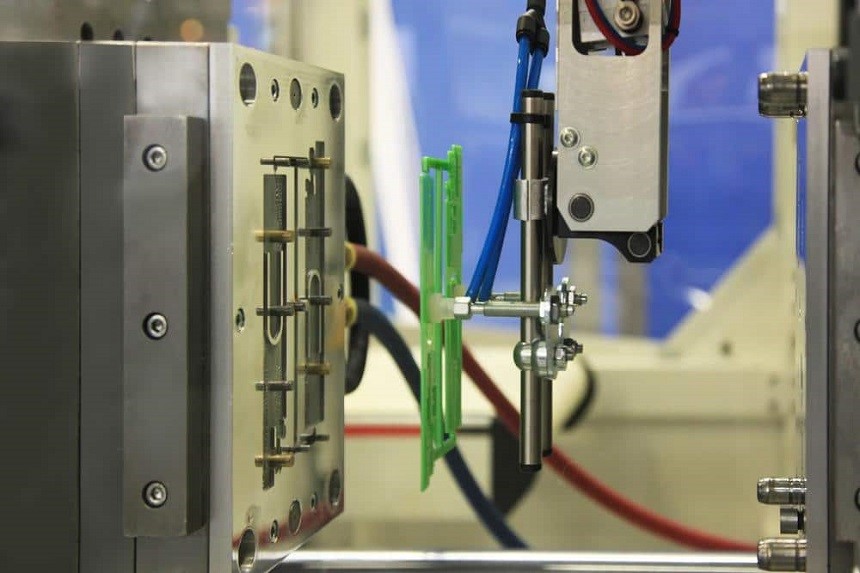

The mold

Mold is a hollow metal block in which a particular compound is injected. The mold can be created from different materials, each of which brings a number of benefits to the injection molding process.

For instance, while it’s costly to produce steel molds, they usually live longer than molds made from other materials, which makes them a valuable investment in the long run. Following are the two main parts of injection molds:

- A plate (injection mold)

- B plate (ejector mold)

The injection machine

Most injection machines comprise two individual units—the unit in charge of clamping and the unit in charge of injection. The clamping unit opens/closes a die while the injection unit injects the compound into the mold.

Injection molding uses two distinct clamping methods—the toggle and straight-hydraulic types, each appropriate for various purposes.

- Benefits of hydraulic clamping: This method offers easier adjustment of clamping force and enhanced control of clamping speed.

- Benefits of toggle clamping: Toggle clamping lowers the costs of the process and lowers energy use.

Get top-of-the-line results with PTMS’ custom plastic injection molding

PTMS is an ISO 9001-2008 certified plastic injection molding company. With 8 QC technicians for every shift in the shop, we ensure that only high-quality products are manufactured.

Get in touch with us now for an injection molding quote online!