How to Speed Up the Injection Molding Process?

The plastic injection molding process is a critical process with a plethora of moving parts. However, this doesn’t mean you can’t make simple changes to speed up the injection molding process.

Read as we highlight how you can speed up the injection molding process.

Consider your material selection

Some materials will have higher flow rates or higher fill pressure ratings. This means they can fill every cavity faster and get into the mold faster. Material selection is usually written off or overlooked, but ensure you research whether or not resin properties may be perfect for your part. Thus, doing this research can help reduce your cycle times by a good margin.

Invest in people – not just in machinery

Efficient, successful injection molding isn’t just about setting up a machine and letting it un, there are numerous adjustments and small tweaks you can make. They can’t all be looked up on a chart or be read in a book.

Often, it’s just a matter of being familiar with a single machine. In addition, talented, experienced injection molding professionals will be able to determine, almost intuitively, the minor adjustments in variables like holding time, cushion, speed, and more than can have a huge impact on cycle times and part quality. Some of the best individuals are probably right in your own company – so ensure you’re giving them opportunities to share their talents and knowledge and train others.

Ensure your machine is fine-tuned

Older injection machines may suffer performance issues, including inconsistent or variable speed and pressure, referred to as fill time. This may lead to scenarios where machines must take longer to inject the same amount of material as a better-maintained or new machine. This means, your cycle times will be greatly reduced.

Errors in fill time or pressure may also result in more rejected parts, which may increase your overall production time and lead to a longer effective cycle time.

Keep wall thicknesses to the minimum required for your product or part to function effectively

This is a minimalist approach to part design, which means that lesser material will need to be injected within mold cavities, incrementally reducing injection time – which can add up to material time savings over many cycles. Don’t forget to consider the required strength of your product walls and comply with the best design practices for minimum wall thicknesses.

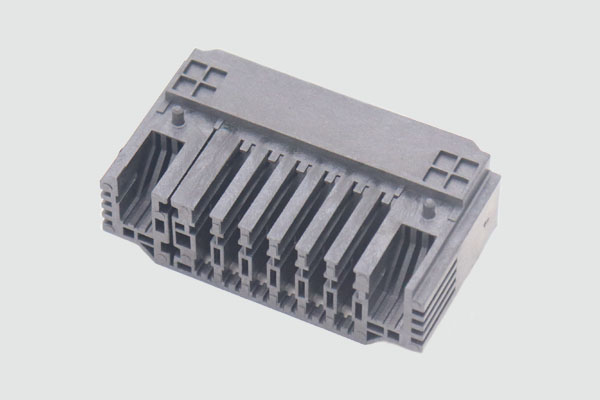

PTMS is your one-stop injection molding services provider

PTMS offers full services, including mold design, plastic injection tooling, plastic injection molding, metal parts, and products assembly. We’ve produced all kinds of top-notch custom plastic parts and metal parts at a reasonable price for different customers around the world.

Contact us now, we’d like to share more than 20 years of experience in all kinds of injection molding mass production with our clients.