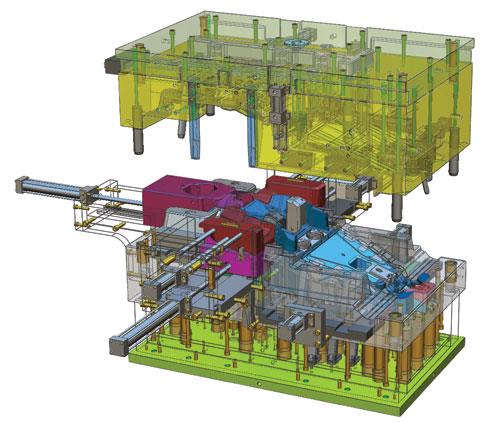

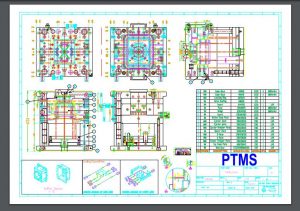

How to Make Plastic Injection Mould Tooling Design?

It’s a little difficult to make perfect plastic injection mould tooling design, because it’s very important for tooling and parts production, also the engineers should consider many factors. Usually, the facts should be some points as below.

The structure of the parts. It includes the part size and structure, if small size, it needs to design small tooling, if big size, big tooling design. Besides, the structure is very important for the designing, simple is easy to do, but for complex design, rather hard to design, many points should be added.

The materials. Its other facts affect the design, normally, it includes ABS, PP, PC, PP+GF, PA, PA+GF, PS, POM, PMMA, PC, PS and etc. because the different materials fit the different mold steel.

Steel of Cavity & Core. Normally, it’s based on the plastic parts, the engineer will choose the good steel material for the different mold. The common are P20, 718, 718H, NAK80, because it’s fit for plastic injection mould design.

Steel of Cavity & Core. Normally, it’s based on the plastic parts, the engineer will choose the good steel material for the different mold. The common are P20, 718, 718H, NAK80, because it’s fit for plastic injection mould design.

The steel of mold base. The common is called S50C, LKM mold base is popular in China and many molds were made by such base, top quality and reasonable price mold based.

Mold Cavities. It depends the part size and structure, normally, single cavity and multi cavities for mold, also the engineer has to consider the injection machine capability.

Others. Such as mold life, treatment, hardness and etc.

There are many facts to affect the plastic injection mold tooling design, we just list some points for your reference. The feature of the mold should be reasonable structure design, good surface treatment, long mold life, shorter deliver time, the best price. PTMS can make all kinds of mould according to the requirement, so just provide us the drawings or the samples, we will make perfect injection mould tool design for you. You will get top quality mould as soon as you choose us.