How Much Does Plastic Injection Molding Cost?

A small and simple single-cavity plastic injection mold typically costed between $1K and $5K back in 2013. Complex and very big molds would cost up to $80K and over. An average mold which manufactures a comparatively simpler component, which would be so small you could hold it in your hands, would cost about $12K.

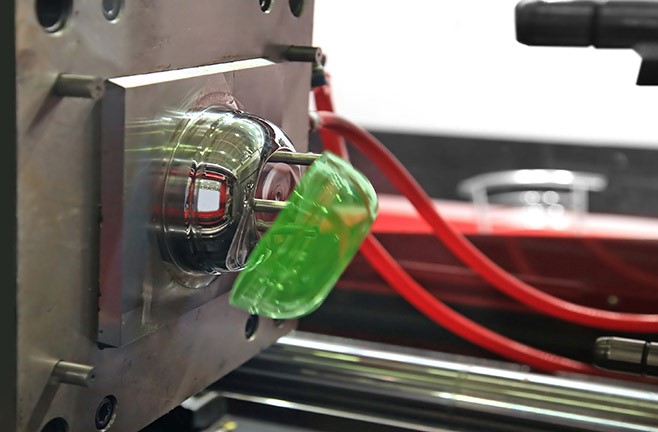

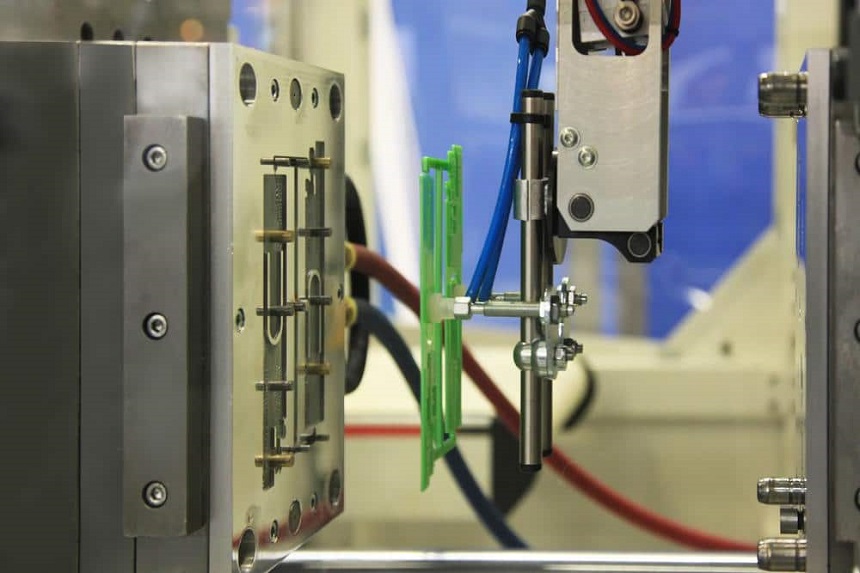

You must be wondering why the cost of plastic injection molding is so high. That is because injection molds are supposed to be made with very strong materials, which are able to endure repetitive use without getting deformed.

This makes asking the cost of plastic injection molding very similar to asking someone, ‘how much would a car cost?’ The answer to that question depends on so many other things, like the type of car you need, and more. Then, the price of the mold is just the tip of the iceberg. If you have to figure out the total plastic injection molding expense of a certain project, considerations like costs of repairs that incur later on, operational costs, and raw material costs will have to be taken into account.

How Much it Costs to Make a Plastic Injection Molding

A number of factors contribute to the final cost of the mold you choose. It will include the following:

- The quantities in which you need your mold

- The material of your plastic injection mold

- The complexity of design of your plastic injection mold

- The size of the plastic injection mold component

For instance, if you need to manufacture 1,000 washers every year, a single-cavity mold would be sufficient for that. That would make it one washer per machine cycle, making the mold would have cost somewhere between $1K-$2K in 2013.

Say you needed 100K Xbox controllers every month. That would be a project having a totally different production scale. We would suggest you build a 12-cavity hardened family mold that would manufacture four Button Trees, four Backs, or Fronts per cycle. But that will obviously cost you more. In 2013, this may have required you to invest $60K to $80K or higher!

While these examples may feel like they are at extremes, they do give a fair idea of the costs you can expect to incur. Your specific component will fall somewhere within the aforementioned range. An average mold at PTMS Tooling & Molding would cost you about $12K.

There is a reason why the cost of injection molding is so expensive. In the beginning, it may cost a lot, but as you continue to produce, the price of the project improves over time. If you look at it from the perspective of unit cost, you will have to pay the lowest price per unit when you choose plastic injection molding. It is the most cost-effective manufacturing method in that way. This means that the more units you manufacture with your mold, the cheaper the price of every unit will become.

The Bottom Line

At the end of the day, you can expect to pay anywhere from $10K to a little close to $100K for plastic injection molding. The cost is driven by complexity of part, order size, and other factors. You may incur high initial expense to set up injection molding, however, the price per unit becomes cheaper as you start producing a greater number of parts, over the long run. This makes it great for companies that need to do mass production of parts!

PTMS is a full-service plastic injection molding company that makes plastic injection molds from concept to final completion stage. We stay true to our quoted prices. The cost of injection molding will depend on the degree of difficulty faced while making it, and the type of tooling that it involves.

If you have a specific price you need for your components, discuss that with your injection mold builder. They will be able to design the mold within your budget, and design just the right number of cavities you need to achieve that price. The more components you manufacture per cycle, the lesser the price per unit will become, encouraging you to expand your total number of units produced.