How Melt and Mold Temperature Affect Plastic Molding Development?

In the machining industry, much emphasis is put on how to change a plastic’s properties. What many people don’t know is that temperature also plays a vital role in this process. The melt and mold temperature can affect your final product – whether it be by changing the flow rate or the viscosity of your material. It is important to know what temperature will produce the best results for your project needs, from plastic injection to thermoforming.

This blog will discuss how melt and mold temperature affect plastic molding development.

Under-melt and frozen melt

If enough heat is not added to the material, you will have an under-melt or frozen melt. An under-melt will cause a lack of fluidity in your final product. On the other hand, frozen melts become too solid and don’t flow appropriately with pressure from molds.

Temperature Variations

The temperature at which your material melts isn’t the only temperature that can impact your final product. The temperature at which you mold your plastic will also have some effect on the final product.

Different materials are molded at different temperatures, and not all plastics can be used in molds of specific temperatures. For example, PVC has a low heat tolerance and cannot be used with molten metals. Here’s a list of different plastics and the maximum mold temperature they can be used with:

Natural Rubber 250°F/121°C

Silicone Rubber 400°F/204°C

Neoprene 350°F/177°C

Acetal 230°F/110°C

PVC 160°F/71°C

Finding a medium between your melt and mold temperature can help ensure a high-quality product. A good rule of thumb is to make sure the temperature you use for molding doesn’t exceed 125°C above your melt temperature. For instance, if you are using a material with a melt temperature of 265°F/129°C, you can mold your material at 392°F/200°C.

Air Bubbles because of Incorrect Cooling

Since plastics shrink when cooled, incorrect cooling temperatures will also lead to air bubbles forming in the final product. Air bubbles are bad for many reasons; they are an unexpected design aspect, cause breakages during transportation and storage, or become weak points where pieces of plastic might break off.

As with melt temperatures, different materials have specific cooling temperatures that can produce high-quality products. Acetal and Delrin should be molded at room temperature. If heated, they may warp or bend because of their low heat tolerance. Nylons require about half an hour to cool down after molding, while PVC takes about 15 minutes.

Use of Correct Tools and Equipment

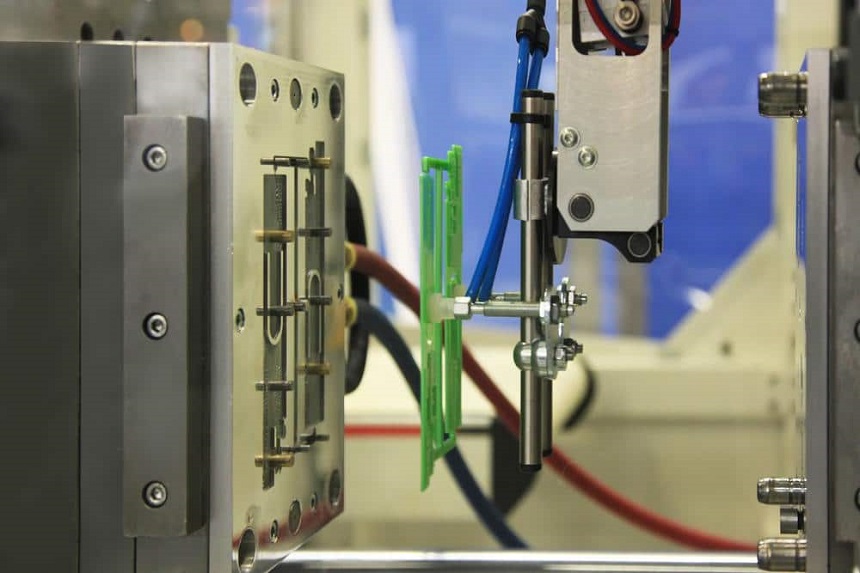

In addition to molding and melting temperature, it’s also essential to choose the correct tool to produce an adequately molded product. For instance, a caulking gun will not suffice for large projects because it does not provide enough force against the plunger. If you are going to use a caulking gun, it is recommended that you have an assistant help you. An injection mold machine is the best tool for large projects; however, it can be challenging to maintain and run properly on your own.

As mentioned before, the temperature of the material will affect how well your final product is molded or formed. Understanding what that temperature is can be beneficial. To do so, you will need to figure out the melting point of your material.

At PTMS, we are one of the best injection mold makers in China. Our team has been offering exceptional project solutions since 2002. It doesn’t matter what the complexity of your project is; we can help you. PTMS will be your reliable injection mold maker for years to come. Contact us now for more information.