Custom Plastic Injection Molding: The Ultimate Industrial Manufacturing Solution

In the industrial manufacturing industry, custom plastic injection molding stands out as a versatile and efficient process for creating high-quality plastic components. This technique involves injecting molten plastic material into a customized injection mold to produce precisely shaped parts. It’s a method that offers numerous advantages, making it a popular choice for various applications.

The Process of Custom Plastic Injection Molding

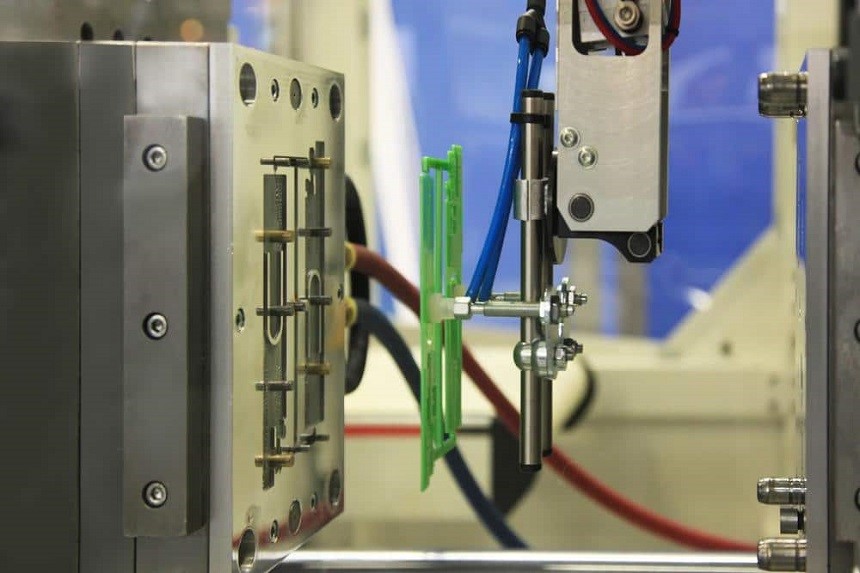

The process begins with the design of the injection mold, which is created based on the specific requirements of the product. This mold is then filled with molten plastic, which hardens as it cools, taking the shape of the mold. The final product is then ejected from the mold, ready for use.

One of the key benefits of custom plastic injection molding is the ability to produce large quantities of uniform parts quickly and efficiently. This makes it an ideal solution for mass production, where consistency and reliability are crucial.

Versatility and Customization

Another significant advantage of custom plastic injection molding is its versatility. With this process, manufacturers can create complex shapes and designs that would be difficult or impossible to achieve with other methods. Additionally, a wide range of plastic materials can be used, allowing for extensive customization based on the specific needs of the application.

Cost-Effectiveness and Durability

Custom plastic injection molding is also cost-effective. The initial investment in mold creation can be high, but the long-term costs are significantly reduced due to the efficiency and scalability of the process. Furthermore, plastic parts produced through injection molding are known for their durability and longevity, making them a reliable choice for various applications.

Applications of Custom Plastic Injection Molding

Custom plastic injection molding finds its applications in numerous industries. From automotive and electronics to medical and consumer products, this process is widely used to create various components. Whether it’s a precision part for a medical device or a durable housing for an electronic product, custom plastic injection molding offers a reliable solution.

Conclusion

In conclusion, custom plastic injection molding stands out as a versatile, efficient, and cost-effective manufacturing process. Its ability to produce high-quality, precisely shaped plastic components makes it an invaluable tool in various industries. Whether you’re looking for durability, customization, or scalability, custom plastic injection molding offers a comprehensive solution for your industrial manufacturing needs.