Crafting Precision: Unveiling the Art of Injection Mold Tooling in China

When it comes to the world of manufacturing, precision is the name of the game. Whether you’re producing a small batch of consumer goods or embarking on a large-scale production journey, the quality of your molds can make or break your project. Enter the world of injection mold tooling in China, where innovation meets precision, and craftsmanship knows no bounds. In this friendly blog post, we’ll explore the fascinating realm of plastic injection mold makers in China. Get ready to dive into a world where technology and artistry collide to create the molds that shape our daily lives.

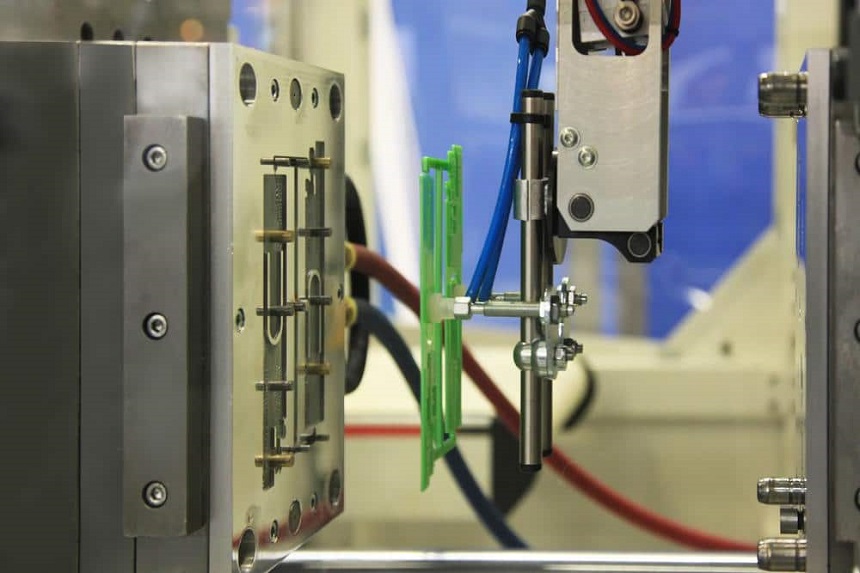

The Artistry of Injection Mold Tooling

At the heart of every great product is a meticulously crafted mold. Injection mold tooling in China is an art that combines technology and craftsmanship. These skilled professionals are like the sculptors of the manufacturing world, shaping raw materials into the precise forms required for countless products. From intricate details to complex geometries, they’re the unsung heroes behind many of the items we use daily.

The Rise of Plastic Injection Mold Makers in China

China has emerged as a global leader in manufacturing, and its prowess extends to the realm of injection mold making. The country boasts a robust industry of plastic injection mold makers, and there’s a good reason for that. The combination of cost-effective production, advanced technology, and a skilled labor force makes China the go-to destination for businesses seeking high-quality molds.

Innovations in Injection Mold Technology

One of the driving forces behind China’s dominance in injection mold tooling is its relentless pursuit of innovation. From 3D printing to computer-aided design (CAD), these mold makers embrace cutting-edge technology to push the boundaries of what’s possible. This forward-thinking approach allows them to create molds that are not only highly precise but also incredibly efficient.

Collaborating with Injection Mold Makers in China

Thinking about partnering with an injection mold maker in China? It’s a decision that could revolutionize your manufacturing process. These professionals are known for their attention to detail and commitment to quality. By collaborating with them, you can ensure that your products are not only of the highest quality but also cost-effective in the long run.

The Advantages of Injection Mold Tooling in China

What makes China stand out as the destination for plastic injection mold making? There are several advantages to consider. Firstly, cost-effectiveness – China offers competitive prices without compromising on quality. Secondly, a vast network of suppliers and manufacturers that facilitates a streamlined production process. Lastly, the speed of production – China’s mold makers are known for their ability to meet tight deadlines without sacrificing quality.

Quality Assurance in Injection Mold Making

When it comes to plastic injection mold making in China, quality assurance is paramount. These professionals understand the importance of meeting international standards and have stringent quality control measures in place. From material selection to post-production inspection, every step is meticulously executed to ensure that the molds meet and exceed expectations.

Sustainability in Injection Mold Making

In today’s environmentally conscious world, sustainability is a key consideration in manufacturing. Injection mold makers in China are increasingly adopting eco-friendly practices. This includes the use of recyclable materials, energy-efficient production processes, and waste reduction initiatives. By partnering with these forward-thinking professionals, you can contribute to a more sustainable future.

Frequently Asked Questions (FAQ)

Q1: What types of products can benefit from injection mold tooling in China?

A1: Virtually any product that requires precision and consistency in its manufacturing process can benefit from injection mold tooling in China. This includes items like automotive components, medical devices, consumer electronics, and household goods.

Q2: How long does it take to create an injection mold in China?

A2: The timeline for creating an injection mold can vary depending on factors such as complexity, size, and the availability of resources. However, many mold makers in China are known for their efficiency and ability to meet tight deadlines. Typically, it can take anywhere from a few weeks to a couple of months.

Q3: Are there language barriers when working with Chinese injection mold makers?

A3: Language barriers can sometimes be a concern, but many mold makers in China have multilingual teams or employ translators to facilitate communication with international clients. Additionally, clear and detailed technical specifications can help minimize potential misunderstandings.

Q4: How can I ensure the quality of injection molds produced in China?

A4: Ensuring the quality of molds produced in China involves thorough research and due diligence when selecting a mold maker. Look for certifications, reviews from past clients, and request samples or prototypes to evaluate the quality before proceeding with injection molding mass production.

In conclusion, the world of injection mold tooling in China is a testament to human ingenuity and dedication. These skilled artisans, armed with cutting-edge technology and a commitment to excellence, play a pivotal role in shaping the products that enrich our lives. So, whether you’re in the early stages of product development or seeking to improve an existing manufacturing process, consider the artistry of injection mold makers in China to take your project to the next level. With their expertise and your vision, the possibilities are endless.