Benefits of Plastic Injection Mold Tooling from PTMS in China

In recent years, the injection mold industry in China has witnessed exponential growth, with an increasing number of companies recognizing the numerous benefits of plastic injection mold tooling. As the demand for injection mold services continues to soar, it becomes crucial to understand the distinctions between injection mold, as well as why choosing plastic injection mold tooling from PTMS is a wise decision.

1. The Rising Demand for Injection Mold Tooling in China:

With its thriving manufacturing sector and attractive cost advantages, China has become a hub for injection mold tooling. The nation’s sophisticated infrastructure, skilled labor force, and access to advanced technology have propelled China to the forefront of the industry.

2. Understanding the Key Differences: Injection Mold vs. Injection Mould Tooling:

While both injection mold and injection mould tooling involve the creation of molds for plastic manufacturing processes, there are notable distinctions. This section will delve into the nuances, highlighting factors such as design flexibility, ease of customization, and part production efficiency.

3. The Advantages of Choosing Plastic Injection Mold Tooling for Your Manufacturing Needs:

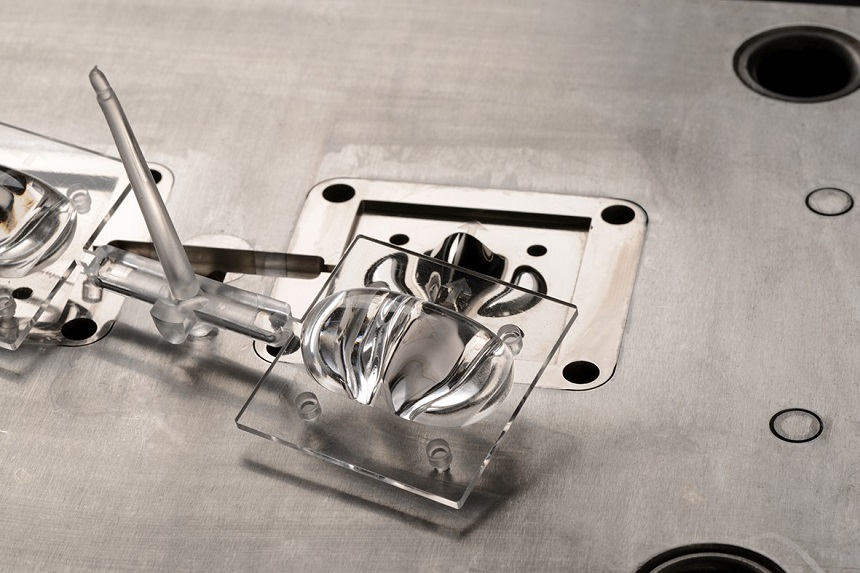

Plastic injection mold tooling offers a plethora of advantages, making it the preferred choice for many companies. This section will explore the benefits, which include cost-effectiveness, high precision, rapid production cycles, and the ability to create complex geometries, among others.

4. Enhancing Precision and Efficiency with Plastic Injection Tooling:

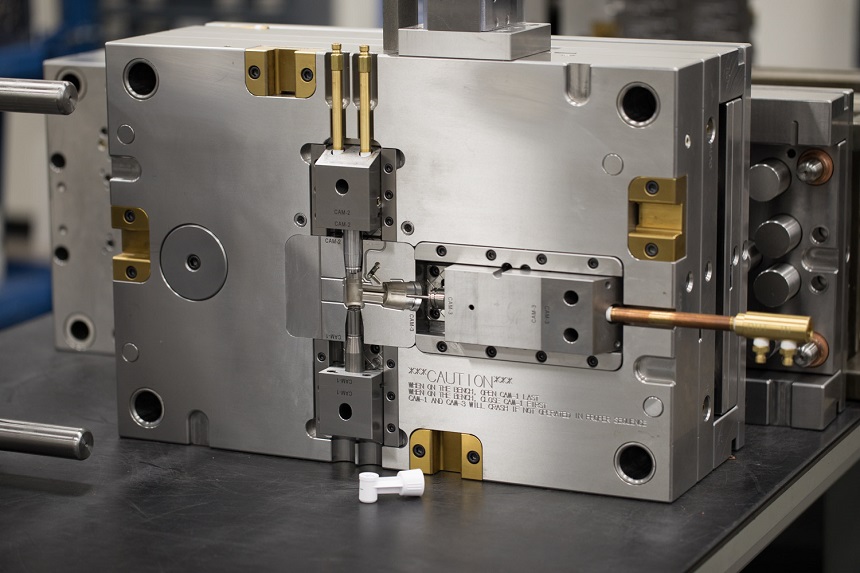

Plastic Injection Tooling involves the creation of intricate molds, into which molten plastic is injected under high pressure. The molds are designed with meticulous attention to detail, ensuring the production of consistent and flawless components. Plastic injection tooling boasts exceptional accuracy, yielding complex shapes and intricate details. By utilizing advanced computer simulations and CAD/CAM technologies, manufacturers can fine-tune the tooling process, reducing the likelihood of defects and material wastage.

5. Spotlight on PTMS: A Trusted Provider of High-Quality Plastic Injection Tooling:

As businesses seek reliable plastic injection mold tooling, PTMS has emerged as a distinguished player in the industry. This section will focus on PTMS’ extensive experience, commitment to quality, advanced manufacturing facilities, and customer-centric approach.

6. Leveraging PTMS’ Expertise: Why They Should be Your Preferred Choice:

In this final section, we will delve into the unique advantages of choosing PTMS for your plastic injection mold tooling needs. With a track record of delivering top-notch products and services, PTMS stands out in terms of their technical expertise, cost-effectiveness, quick turnaround times, and exceptional customer support.

Conclusion:

With the injection mold industry in China flourishing, it is essential to understand the distinctions between various types of tooling. Plastic injection mold tooling has gained immense popularity due to its numerous advantages, and PTMS has established itself as a reliable provider in this space. By leveraging PTMS’ expertise, manufacturers can enjoy high-quality, cost-effective, and efficient plastic injection mold tooling that meet their specific requirements.