6 Questions To Ask Before Purchasing Injection Molds

When purchasing injection molds, attention is critical to stress-free manufacturing and long-term success. While some mold design aspects must be considered as early as the start of the product development phase, others begin when the tool order is placed. In this process, the main goal of the project manager is to keep the customers happy without creating manufacturing problems.

Here, our plastic injection molding company highlights six questions to ask before purchasing injection molds:

1. What is the part’s size, material, and geometry like?

Based on what size, features, and geometries you want for your plastic parts, your prospective mold-making partner may have to use a variety of mold-making approaches. A few designs will require molds made using steel inserts, or hardened steel, instead of softer metals such as aluminum.

The material you’re looking to use for your plastic parts will also play an important role in how the mold is designed and produced. Not every resin is compatible with every mold material. For instance, plastics like nylon will need a better quality mold to fit part specifications.

The molding engineers at PTMS can help you analyze the specifications of your parts to ascertain what type of mold best suits your requirements. We’ll also assess overall functionality to help in the mold design process — considering other features such as breakaways, snap fits, etc., to design the right mold.

2. Where am I in product development?

This is one of the most crucial factors. In the early phases of pre-production and prototyping, expecting a lower construction quality mold is fine because they’re created to make short runs of your prototype, which makes design iterations cost-effective.

However, if you’re deep in the development phase, you can request a sturdier, better-built mold that is production-ready. Choose your mold wisely — to avoid spending more money on mold repairs and new molds, ensure its suitable for where you are in your product development process.

3. How much will the initial mold build cost?

You should get a quote early on to see if it aligns with your production budget. Many factors impact your mold’s cost, including specialty molding designs, mold cavitation, design complexity, and mold classification.

For instance, a final mold costs more than prototype molds. Plus, having a specialized design, like a multi-cavity mold, can also raise initial build costs.

Decide what you want for your molds and be upfront. This helps your partner understand what goes into your mold-making price. And professional mold makers such as PTMS will help you find ways to make your design more cost-effective, ensuring you get the most bang for your buck.

4. How long will it take to build?

Building a new mold is one lengthy task. While it’s possible to design and make certain molds in a couple of weeks, others may take several months. So, don’t hesitate to present your part design and ask your potential partner what the lead time will be for your mold. This will help you adjust your production schedule.

If you still need to tweak your part design, you can ask for a prototype mold, which doesn’t take more than 3 to 6 weeks. However, if you’re ready for full production, your mold may take more than a dozen weeks to make.

But the important thing is that your molding partner has a good idea of what to make and how much time they need to make it. If they can provide intermediary solutions to help with huge lead times, then your production will benefit from it.

5. What standards do they follow?

The most important standard includes ISO 9001:2008 for product consistency and quality. If your injection molder adheres to this standard, as PTMS does, you can rest assured knowing that the mold maker will do everything in its capacity to meet and exceed quality requirements.

6. What is the molder’s expertise?

Most injection molders have their areas of expertise. So, asking this question is important as it’ll help you identify whether or not they have the knowledge and experience to make the best mold for your application.

You can either ask them directly about their reputation, equipment list, and portfolio or check their website. You’ll come across a testimony of the stability and quality of their products and service. Also, ask for a few of their client references, especially those who work in the same field as you. This will help you determine whether or not this injection molding company can meet your industry’s specific requirements.

Benefits of outsourcing plastic injection molding

Great production support

When you outsource your plastic injection molding, you’re able to access the provider’s service, manpower, resources, and equipment. These can make all the difference between a streamlined, efficient, and cost-effective process that comes in on budget and on time (or better); or troubleshooting, difficulties, and overruns (which may require external personnel anyway if done in-house).

With the right injection molding provider, you’ll get strong production support, which will offer you the full benefits of outsourcing. This support can help with questions in all areas of your process if required – fulfillment, QA, production, prototyping, engineering, design, concept, and more. Plus, good production teams can step in/out at any time, helping you meet your specific needs.

Improved quality

If you choose to work with the right company for injection molding, you’ll be able to benefit from their extensive experience and expertise in the process. Naturally, all of this expertise means you’ll get a high level of quality in the process and the finished product.

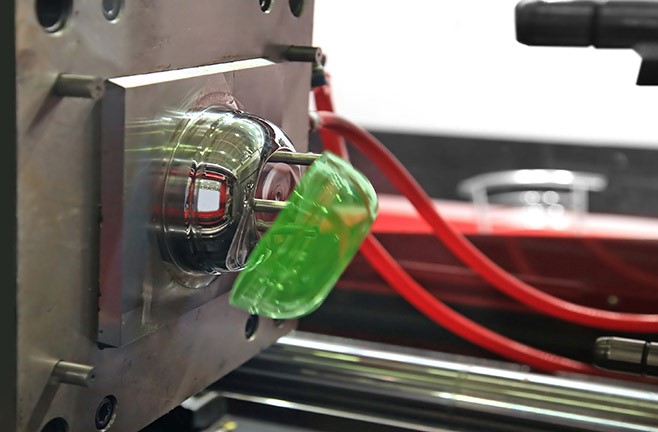

Often, injection molding is referred to as both science and art, and even researching hints, tips, best practices, processes, and more, can’t replace someone who has been working with a specific machine for years, or an engineer with decades of experience. The ability to intuitively adjust and fine-tune aspects of the complex injection molding process impacts many areas – from turnaround time and troubleshooting to product quality and more.

Moreover, an outsourced injection molding provider has higher chances of having the resources to invest in quality assurance practices and tools, training, and quality certifications to name a few. With a molding provider by your side, you’ll be able to access these resources, as well as their experience and the quality they provide.

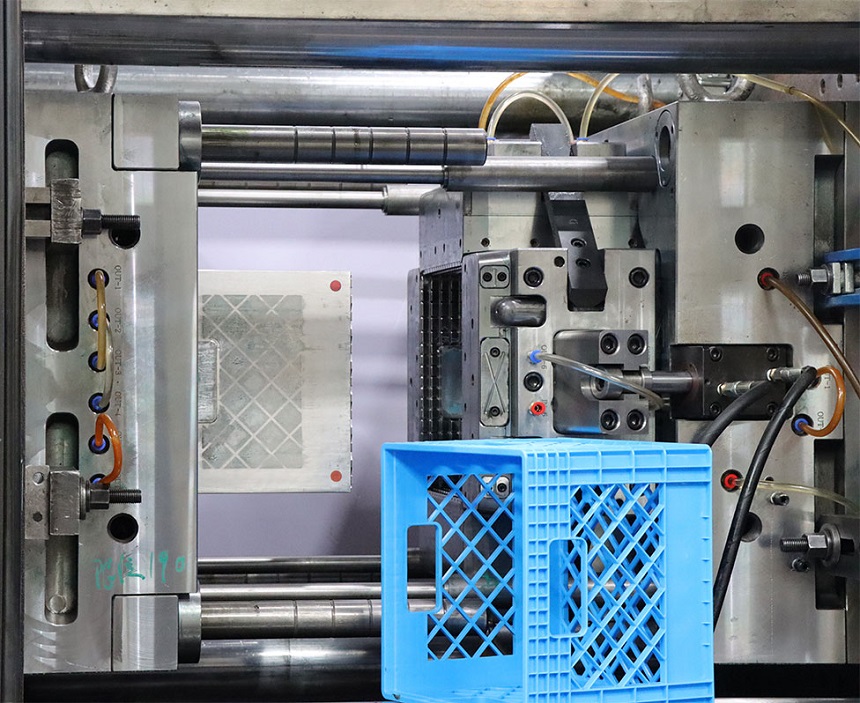

PTMS — the best plastic injection molding manufacturer — offers custom plastic injection molding using 100% brand new materials

With years of experience in plastic injection molding mass production, PTMS has been offering customers top-of-the-line custom plastic injection molding for almost two decades.

Get in touch with us now to get an injection molding quote from our plastic injection molding company!