5 Design Considerations for Injection Molded Products

If you’re looking to design a mold, don’t forget to consider the following important plastic injection molding design checklist.

1. Ribs

Plastic has a stiff nature. Keeping this in mind, the inclusion of ribs in a design is usually suggested, which adds to the bending stiffness. There’s no better option than ribs when it comes to convenience and pocket-friendliness, the final outcome of which is usually well received by both the manufacturer and the designer.

However, a designer should always consider the wall thickness at the time of incorporating a rib in a plastic design. Deep and thick ribs may lead to filling problems and sink marks respectively. Never let the rib thickness of a part exceed the wall thickness.

2. Draft

While plastic is being removed from the mold, it heavily relies on mold drafts. This is why plastic injection molded parts should be designed with a draft (or a taper) in the direction in which the mold moves. In cases like these, the absence of an appropriate draft would make the removal of plastic parts pretty challenging.

Designs with sufficient drafts are always preferred. Typically, design experts recommend 1.5 degrees for a depth of 0.25mm. According to general guidelines, a draft angle of 1.0 degrees is recommended for the cavity and 0.5 degrees for the core.

3. Identify an apt location for gate

Although it’s suggested to have a plastic design with a uniform wall thickness, there may be variations in a few designs. In such situations, the success of the part will be decided by an appropriate gate location. According to experts, the gate must be placed at a location where the melt enters the cavity’s thickest section only to flow out of a narrower region.

4. Wall thickness

Keeping in view the different nature of the composition of plastics, plastic parts should always have walls with uniform thickness. Unfavorable incidents like warpage and shrinkage may occur if recommended guidelines are not followed.

Besides this, you get the assurance of minimum manufacturing cost with uniform wall thickness. This, in turn, ensures quick cooling, which allows optimum utilization of resources and production of multiple parts in a short time frame.

Here’s what the guidelines say: wall thicknesses for unfilled materials should be 0.5mm to 5mm, and those for reinforced plastic materials should be between the range of 0.75mm to 3mm.

5. Radius

There’s always a need to accommodate large radii when there’s a design with corners. Since sharp corners spell stress, they affect the manufacture ability of the parts. Corners like the attachment between surfaces and bosses that are usually overlooked require scrutiny.

The radius should always be kept in line with the part thickness, eradicating the prospects of high-stress concentration, which results in the breakage of the plastic part. According to general guidelines, the thickness at the corner should be between 0.9 to 1.2 times the nominal thickness of the part.

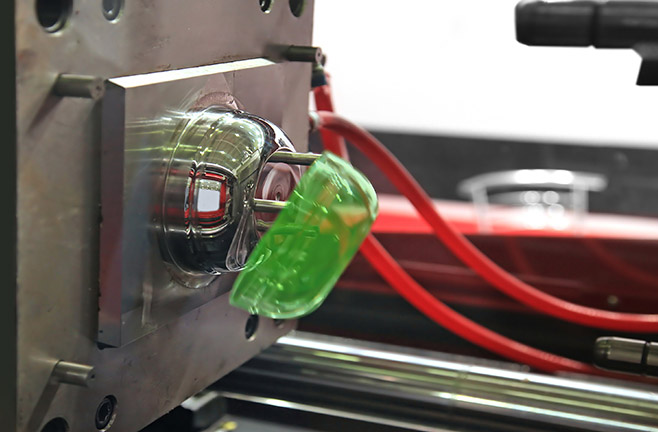

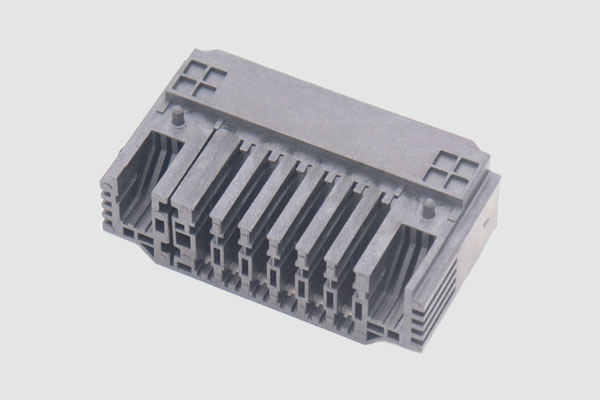

PTMS makes custom injection molding with advanced injection machines.

PTMS’ injection molding shop can mass-produce plastic injection molding parts for customers every day.

Get in touch with us for more information on our plastic injection molding!